Exactly How to Ensure Durability and Integrity with a High-Quality Membrane Switch

Exactly How to Ensure Durability and Integrity with a High-Quality Membrane Switch

Blog Article

Discovering the Benefits of Membrane Switches Over in Modern Electronic Devices

The integration of membrane layer changes into modern-day electronic tools presents numerous compelling benefits that warrant consideration. Their layout adaptability permits a high level of personalization, satisfying particular branding and useful demands across various sectors. Paired with their remarkable resilience, these buttons stand up to challenging environments, thus extending their functional lifespan. The cost-effectiveness of membrane switches over settings them as a practical option for makers looking for to optimize their product offerings. Nevertheless, the complete effect of these features on customer experience and functional effectiveness warrants further exam.

Layout Versatility

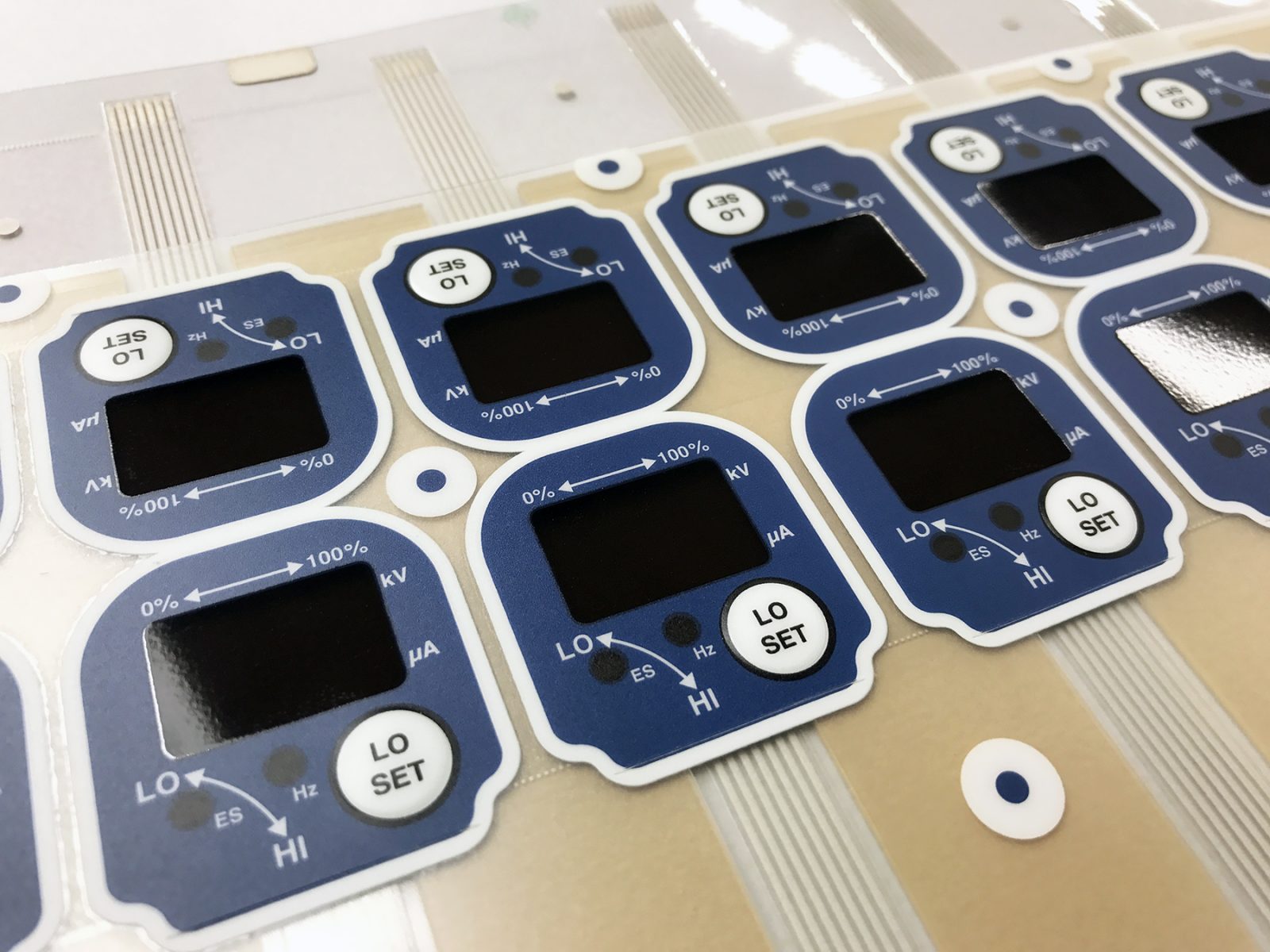

Layout flexibility is a critical advantage of membrane buttons, making it possible for makers to develop tailored interfaces that fulfill particular operational requirements. This versatility is important in an age where user experience and functionality are paramount. Membrane layer buttons can be designed in various shapes, dimensions, and shades, enabling visual assimilation right into varied digital tools.

The published graphics can be tailored to match branding, while the responsive responses can be gotten used to improve individual communication. Additionally, membrane buttons can include numerous layers, enabling features such as backlighting and safety overlays, which add to both aesthetic appeal and performance.

Manufacturers can also utilize various materials, such as polyester or polycarbonate, to line up with specific application demands. This convenience reaches the setup of the button design, allowing the combination of multiple features within a single interface.

The capacity to personalize not just enhances the use of electronic devices yet also enables for the unification of innovative technologies, such as capacitive touch. Because of this, membrane layer buttons are an optimal choice for a wide variety of applications, ranging from medical equipment to consumer electronic devices, making certain that individual demands are continually met.

Toughness and Durability

Durability and durability are vital aspects that improve the appeal of membrane layer buttons in modern digital devices. These buttons are created to withstand tough settings, including direct exposure to dampness, dust, and numerous chemicals. The durable products utilized in their building, such as polyester and polycarbonate, add substantially to their resistance versus abrasion and effect, making certain that they maintain functionality also under arduous conditions.

Additionally, membrane buttons are inherently sealed, preventing contaminants from penetrating the inner elements. This covered construction not just prolongs the lifespan of the switches however likewise decreases the regularity of upkeep and substitutes, which is an important facet for producers and end-users alike.

Another benefit is their ability to withstand comprehensive cycles of operation without destruction in performance (Membrane Switch). This particular makes them particularly appropriate for applications requiring frequent usage, such as clinical gadgets, commercial machinery, and consumer electronics

Cost-Effectiveness

In addition, membrane layer buttons are typically created using affordable products and procedures. Their light-weight layout not only lessens shipping expenses however additionally permits simpler assimilation right into electronic tools. This can cause further savings in manufacturing costs, as structured setting up processes minimize labor and time demands.

Additionally, the fundamental simplicity of membrane layer button layouts usually means fewer parts are needed contrasted to conventional mechanical buttons. This decrease in components not only lowers production costs yet also lessens points of failure, boosting integrity and performance.

In sectors where budget restrictions are important, such as customer electronics and industrial applications, the cost-effectiveness of membrane layer switches over becomes specifically advantageous. Their ability to provide regular efficiency at a reduced lifecycle expense positions them as a sensible option for modern electronic equipment. Overall, spending in membrane switches can lead to substantial long-lasting cost savings for companies and customers.

Personalization Options

Modification alternatives for membrane layer switches are substantial, allowing makers to customize these elements to fulfill details application needs. One of the main benefits of membrane layer buttons is their versatility in style. Producers can select from a variety of materials, consisting of polyester, polycarbonate, and acrylic, each offering distinctive advantages in regards to longevity and looks.

In addition, membrane buttons can be tailored in various shapes and sizes to fit distinct device arrangements. This versatility reaches the consolidation of different shades, graphics, and structures, enabling brands to preserve their aesthetic identification while enhancing customer experience (Membrane Switch). In addition, manufacturers can integrate tactile feedback features, such as embossed keys or varying actuation forces, to improve functionality

Custom-made circuit designs allow for particular capabilities, making it possible for suppliers to create switches that provide exactly to their item's demands. Overall, these extensive modification choices make membrane layer changes a compelling choice for modern-day electronic equipment.

Applications in Different Industries

Membrane layer buttons find comprehensive applications throughout a range of markets, showing their adaptability and functionality in many setups (Membrane Switch). In the health care industry, they are frequently made use of in clinical gadgets, such as client monitors and analysis tools, where reliability try this and simplicity of cleaning are critical. Their secured style assists avoid contamination, making them excellent for settings that require rigorous hygiene criteria

In the vehicle sector, membrane buttons play an important role in control panels and dashboards, giving an intuitive user interface for vehicle drivers. The responsive comments and personalized attributes boost individual experience while making sure resilience against resonances and ecological factors.

Additionally, in commercial applications, membrane layer switches are utilized in equipment control systems, allowing for direct and effective individual communication. With their adaptability, membrane layer buttons offer a robust solution that meets the diverse needs these days's technology-driven sectors, confirming vital for both capability and aesthetic allure.

Conclusion

In conclusion, membrane switches deal significant benefits in contemporary digital tools due to their layout versatility, resilience, and cost-effectiveness. The light-weight nature of membrane go to my site switches over additional adds to decreased delivery expenses and convenience of integration.

Report this page